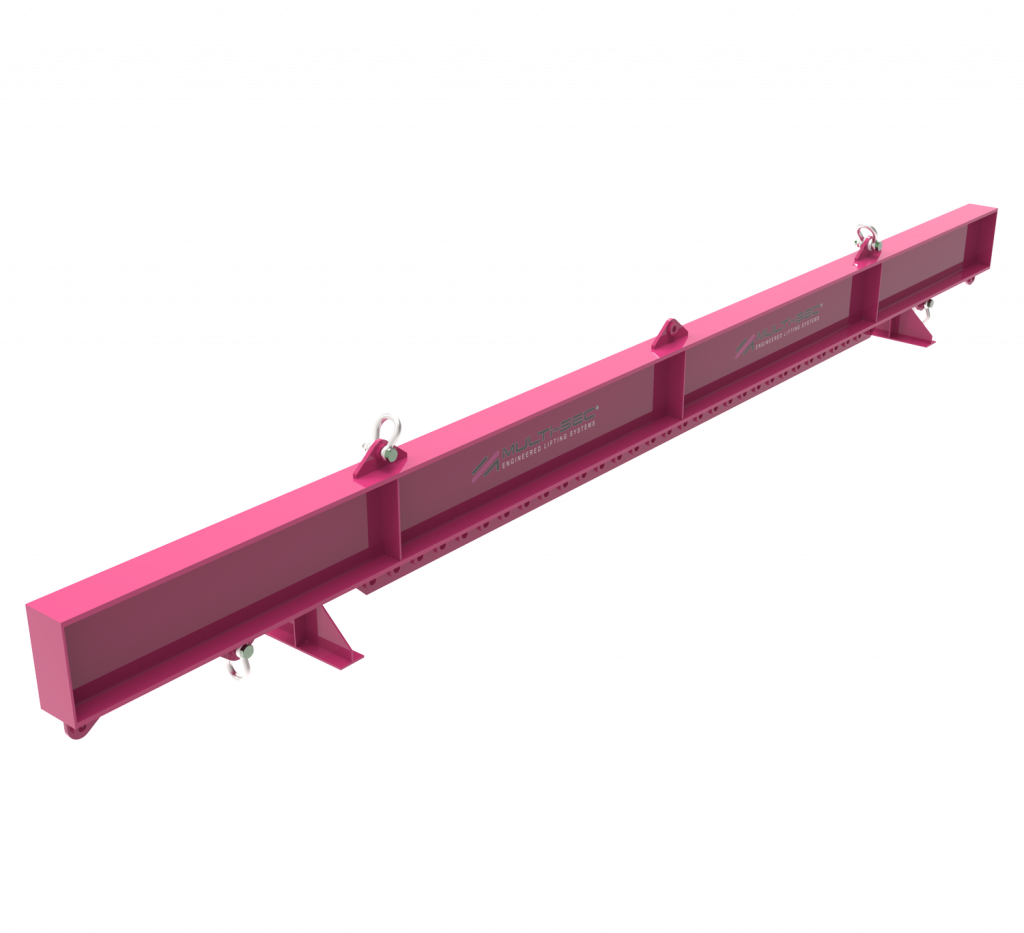

MultiSec Lifting Beams are the perfect solution when a lift has restricted headroom, and are appropriate for lifting large, unstable loads. The basic configuration has a single attachment location, or lug, at the centre of the top side of the beam for connection to a lifting device, such as a crane or hoist. The load attaches to the beam through two or more evenly spaced lugs along the bottom side of the beam, which allows for the weight to be evenly distributed, and prevents sagging and shifting.

MultiSec Spreader Beams, sometimes called Spreader Bars, can be used when the centre of gravity of the lift is offset. The basic configuration has two slings attached to lugs at each end of the beam, which connects to a lifting device, such as a hoist or crane. Like a lifting beam, the load attaches to the beam through two or more evenly spaced lugs along the bottom side of the beam, which allows for the weight to be evenly distributed, and prevents sagging and shifting.

The entire range of MultiSec Lifting Systems are proof load tested in-house prior to despatch and supplied complete with relevant certification.

Contact our team today to learn how we can provide the perfect lifting solution for your next project.

A lifting beam is a load-bearing device that is used to lift heavy loads safely and securely. It is designed to distribute the weight of the load evenly, and can be used in conjunction with slings, chains, or other lifting devices.

A spreader bar is a type of lifting device that is used to spread the load of a heavy object across a wider area. It is typically used in conjunction with lifting slings or chains to prevent damage to the object being lifted.

A lifting beam and a spreader bar are two types of lifting devices used in material handling and lifting operations, but they have different designs and applications.

A lifting beam is a straight bar with a single attachment point on the top, typically used for lifting loads with a single lifting point. It is designed to distribute the weight of the load evenly across its length, providing stability and balance during lifting. Lifting beams can be used with various types of lifting equipment such as cranes, hoists, and forklifts. They are often used to lift heavy loads that are long or awkwardly shaped.

A spreader bar, on the other hand, has two or more attachment points on the top and is designed to lift loads with multiple lifting points. It is typically used to spread out the load and balance the weight distribution, making it safer and more efficient to lift. Spreader bars can be adjusted to accommodate different lifting widths and can be used with various types of lifting equipment.

The use of lifting beams and spreader bars provides a number of benefits, including increased safety, improved load stability, and reduced risk of damage to the object being lifted. They are also easy to use and can be customized to meet the specific needs of a particular job.

Lifting beams and spreader bars are commonly used in a variety of industries, including construction, manufacturing, and transportation. They are used to lift heavy objects such as machinery, equipment, and materials, as well as to move large items into place.

The right lifting beam or spreader bar will depend on a number of factors, including the weight of the load, the size and shape of the object being lifted, and the lifting method being used. It is important to consult with a qualified lifting equipment supplier to ensure that you choose the right device for your specific needs.

When using lifting beams and spreader bars, it is important to follow all safety guidelines and procedures to ensure the safety of the operator and anyone in the vicinity of the lifting operation. This includes proper use of personal protective equipment, proper rigging techniques, and regular maintenance and inspection of the lifting equipment.

Regular maintenance and inspection of lifting equipment is critical to ensure safe and reliable operation. This includes regular cleaning, lubrication, and inspection of all components, as well as the replacement of any worn or damaged parts. It is important to follow the manufacturer’s recommendations for maintenance and inspection, and to have your equipment inspected by a qualified professional on a regular basis.

Designed and manufactured in accordance with:

If you need help or have any questions, please do not hesitate to contact our sales team for guidance.

This product is designed and manufactured in the United Kingdom.